Applications

Additive Manufacturing

ADDITIVE MANUFACTURING

Altering the surface properties of fine powders is an area of ongoing research. The applications for such nanocoated particles are broad and can be found in many different areas of materials science including Additive Manufacturing microelectronics, defense, biomedical, consumer products, advanced materials, and others [1].

The properties of the deposited film are highly important for the nanoparticles applications. The ALD film produced has controllable thickness in the angstrom range, conformal around the entire particle, non-granular, chemically bonded to the substrate, and pinhole or dislocation free.

To conformally coat many grams of nanoparticles with ALD, long precursor soaking steps, fluidized beds, vibrating stages, or rotary feedthroughs can be used [2]. The process can be easily scaled-up by using fluidized bed or rotary tube reactors.

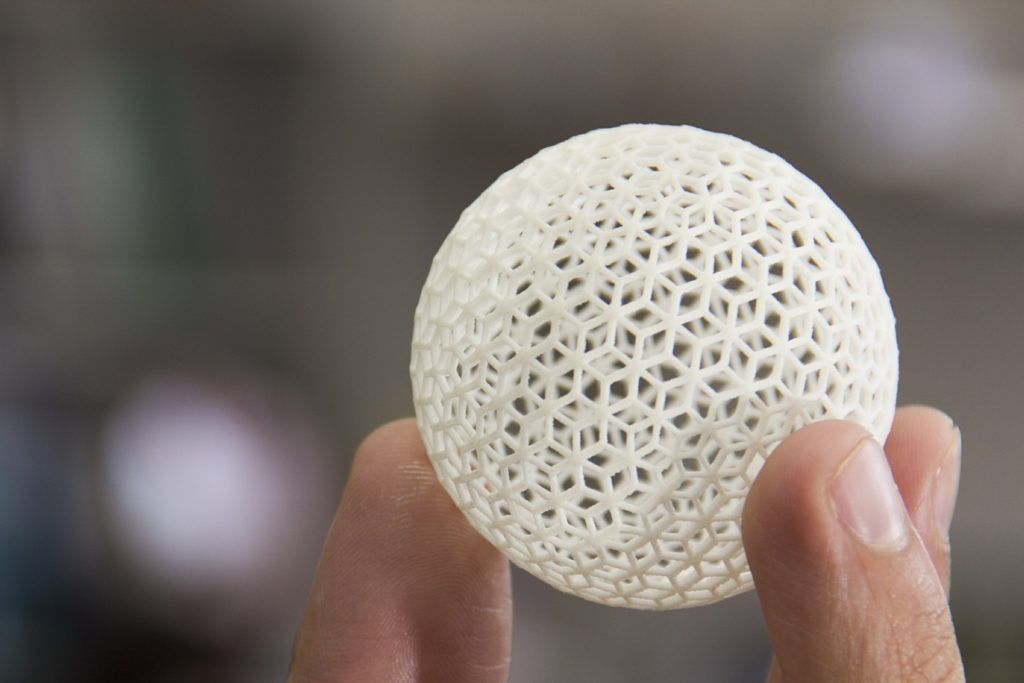

Moreover, due to the conformality of ALD on coating 3D complex shapes substrates it is ideal to give new surface properties to 3D printed materials.

POTENTIAL APPLICATIONS:

- To increase the particle loading on composite materials

- Catalytic/Photocatalytic activity

- Creating diffusion barriers

- Tuning catalysis

- Masking a reactive particle core with a shell

- Powder/Surface functionalitation

- For UV-absorbing

- Core substrate surface passivation

- thermal oxidation resistance

- photocatalytic activity mitigation

- fabrication of electrically insulative metal particles

- Capacitive behavior enhancement

- Protective layer

- Synthesis of bimetallic core/shell nanoparticles

- Optical, electrical and magnetic applications