Atomic Deposition Systems

Design, manufacturing, assembly, test, and delivery of coating tools.

DEPOSITION SYSTEMS

Versatile and high quality ALD and VPI deposition Systems. Find The one that matches your requirements or talk to us and we will try to help you.

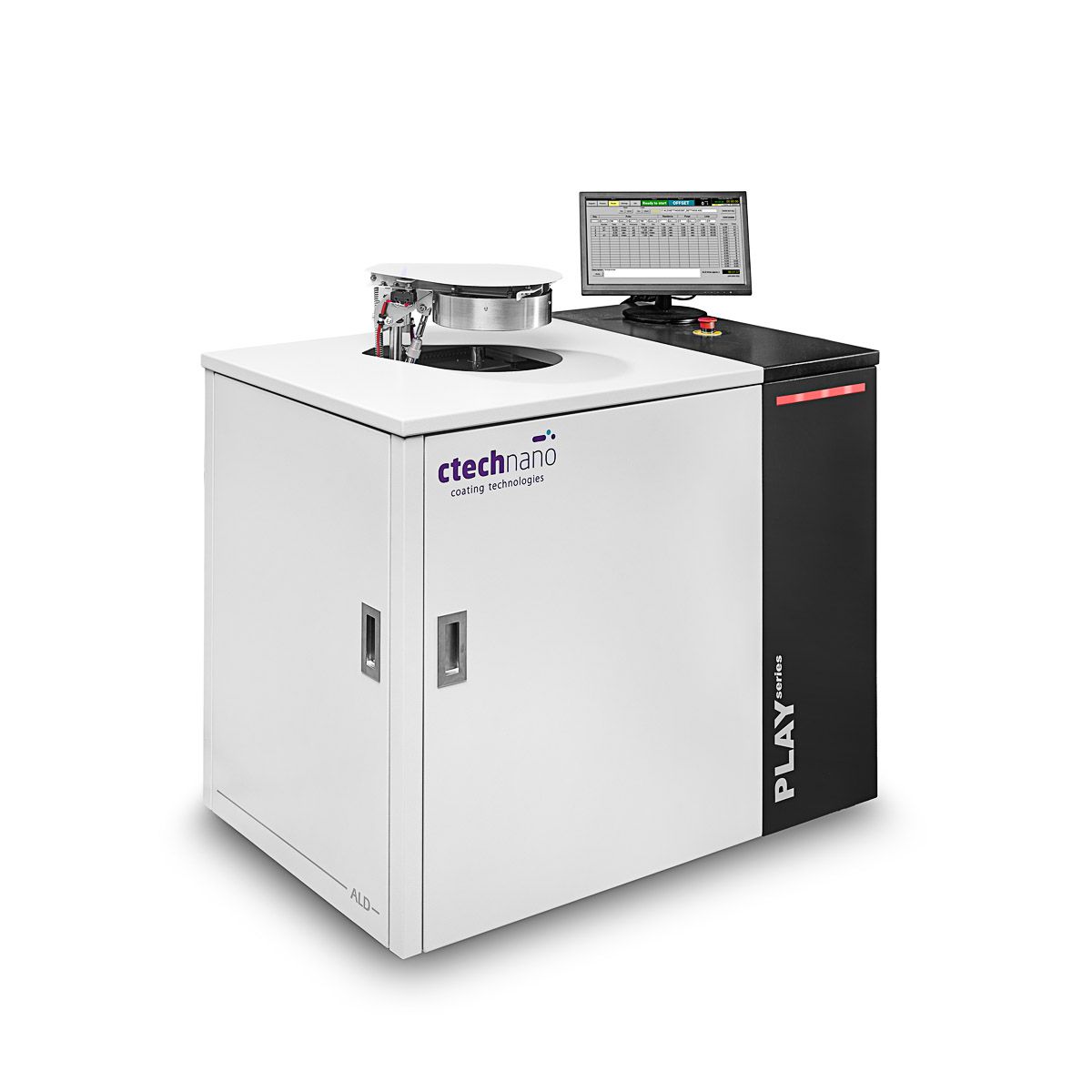

Play Series

WE GIVE YOU THE POSSIBILITY OF UPGRADING YOUR DEPOSITION SYSTEM WHEN YOU WANT BIGGER CHAMBER, PLASMA ALD MODULE, MORE PRECURSORS LINES, ELECTRICAL FEEDTHGROUGHS….

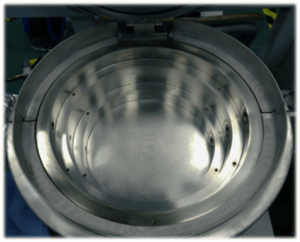

“Chamber available in customized diameters and height”

- Chamber cylindrical shape and engineered flow pattern homogeneity.

- High versatility for many different substrates and deposition materials.

- Precursors, pump, trap, and control, in separated areas for safety purposes.

- User friendly and easy access to all components.

- Stainless steel chamber.

- Precursors feeding system with 4-8 lines for different precursors (cold and hot).

- Precursors feeding system equipped with fast pneumatic valves.

- Multi-section temperature control: – Precursors, heating jackets, range 0-200ºC, resolution 1ºC. – Chamber, range 0-300ºC, resolution 1ºC. – Piping inlet and outlet of the chamber, range 0-150ºC,resolution 1ºC.

- Base pressure 10-1/10-3 mbar.

- Tool dimensions, 1000x600x1000mm.

- Control system with touchscreen:

- System status information: gas flow, temperatures, pressure, and valves.

- Process monitoring: pressure and temperatures. Deviation alarms and safety locks.

- Recipes handling and real time monitoring.

- Customized characteristics upon request.

- Automatic Lid and ergonomic design. Visual and Sound alarms.

• O3 generator, plasma source, QCM, feedthrough: electrical, mechanical….

Flexivol series

DONT BE LIMITED WITH THE SIZES OF YOUR SUBSTRATES. THIS CHAMBER WILL ALLOW YOU TO DEPOSIT SMALL, LARGE AND MANY SAMPLES AT THE SAME TIME.

“Versatile chamber with different adaptable volumes providing efficient coatings for samples of various 2D – 3D shapes and sizes. THREE IN ONE!”

- Chamber cylindrical shape with three different volumes adpatable to your substrates sizes.

- High versatility for many different substrates and deposition materials.

- Precursors, pump, trap, and control, in separated areas for safety purposes.

- User friendly and easy access to all components.

- Stainless steel chamber.

- Precursors feeding system with 4-8 lines for different precursors (cold and hot).

- Precursors feeding system equipped with fast pneumatic valves.

- Multi-section temperature control:

- Precursors, heating jackets, range 0-200ºC, resolution 1ºC.

- Chamber, range 0-300ºC, resolution 1ºC.

- Piping inlet and outlet of the chamber, range 0-150ºC,resolution 1ºC.

- Base pressure 10-1/10-3 mbar.

- Tool dimensions, 1000x600x1000mm.

- Control system with touchscreen:

- System status information: gas flow, temperatures, pressure, and valves.

- Process monitoring: pressure and temperatures. Deviation alarms and safety locks.

- Recipes handling and real time monitoring.

- Customized characteristics upon request.

- Automatic Lid and ergonomic design. Visual and Sound alarms.

• O3 generator, plasma source, QCM, feedthrough: electrical, mechanical….

Essence Series

STARTER MODEL, FOR THOSE WHO DONT NEED MUCH OR HAVE LIMITED BUDGET, BUT STILL WANT HIGH QUALITY.

- Chamber cylindrical shape and engineered flow pattern homogeneity.

- High versatility for many different substrates and deposition materials.

- Precursors, pump, trap, and control, in separated areas for safety purposes.

- User friendly and easy access to all components.

- Stainless steel chamber.

- Precursors feeding system with 4-8 lines for different precursors (cold and hot).

- Precursors feeding system equipped with fast pneumatic valves.

- Multi-section temperature control:

- Chamber, range 0-300ºC, resolution 1ºC.

- Piping inlet and outlet of the chamber, range 0-150ºC,resolution 1ºC.

- Base pressure 10-1/10-3 mbar.

- Tool dimensions, 600x600x600mm.

- Control system with touchscreen:

- System status information: gas flow, temperatures, pressure, and valves.

- Process monitoring: pressure and temperatures. Deviation alarms and safety locks.

- Recipes handling and real time monitoring.

- Customized characteristics upon request.

- Automatic Lid and ergonomic design. Visual and Sound alarms.

• O3 generator, plasma source, QCM, feedthrough: electrical, mechanical….

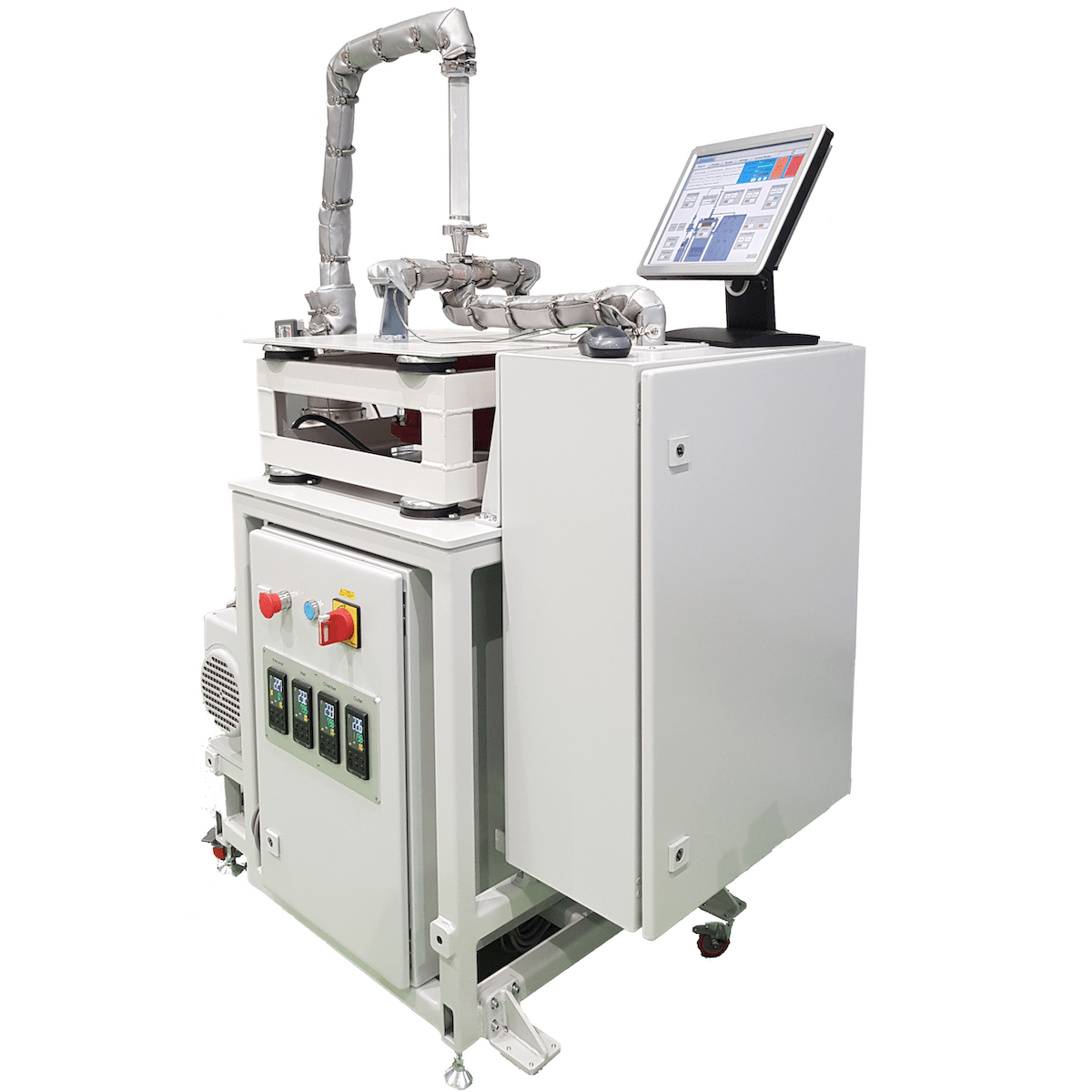

Stardust Series

FLUIDIZED BED REACTOR PROVIDING EFFICIENT COATINGS FOR SAMPLES OF VARIOUS 0D – 1D SHAPES AND SIZES.

- Reactor with cylindrical shape and engineered flow pattern homogeneity.

- High versatility for many different substrates and deposition materials.

- Precursors, pump, trap, and control, in separated areas for safety purposes.

- User friendly and easy access to all components.

- Small or medium size reactor: up to 50 g or 10 kg, substrate load.

- Stainless steel and borosilicate glass reactors.

- Precursors feeding system with 2-4 lines. Different precursors (cold and hot).

- Precursors feeding system equipped with fast pneumatic valves.

- Fluidization: Induced vibration and gas flow.

- Filters to prevent particles leaving reactor.

- Multi-section temperature control:

- Precursors, heating jackets, range 0-200ºC, resolution 1ºC.

- Chamber, range 0-200ºC, resolution 1ºC.

- Piping inlet and outlet of the chamber, range 0-150ºC, resolution 1ºC.

- Base pressure 10-1/10-3 mbar.

- Tool dimensions: 1100x600x1600 mm.

- Control system with touchscreen:

- System status information: gas flow, temperatures, pressure, and valves.

- Process monitoring: pressure and temperatures. Deviation alarms and safety locks.

- Recipes handling and real time monitoring.

- Customized characteristics upon request.

- Ergonomic design. Visual and alarms.

- O3 generator, plasma source, residual gas analyzer…

INDUSTRIAL SYSTEMS

Contact us with your requirements and we will design your specific deposition system.