What is Vapor Phase Infiltration

VPI: Vapor Phase Infiltration

In contrast to a defined interface between substrate and coating, this process can fabricate material blends often with exciting physical or chemical properties. Depending on the chemical and/or physical characteristics of the chosen substrate and the match with a metal precursor, the mechanical, electronic, catalytic, or optical properties of a polymer can be altered. VPI includes various processing modes and each mode can be further tuned to obtain homogeneous infiltration, gradients of densities, embedded nanoparticles or material blends with controlled ratios of inorganic and polymeric phases. Typical application fields of the resulting materials include mechanical reinforcement of fibrous materials, tuning of electronic conductivities, enhancing of etching resists upon lithographic processes, and many more…

The first intentional use of the VPI process was performed on spider silk with standard precursors and process setup as used in an ALD process. The only difference while processing was the extension of exposure times. The process was named Multiple Pulsed Vapor-Phase Infiltration (MPI) for distinguishing the typical ALD coating process from this new infiltration process. Subsequently, several variations of vapor phase infiltration were reported with slight variations in the precursor pulsing strategies, each with a slightly different name, such as, Sequential Vapor Infiltration (SVI), or Sequential Infiltration Synthesis (SIS).

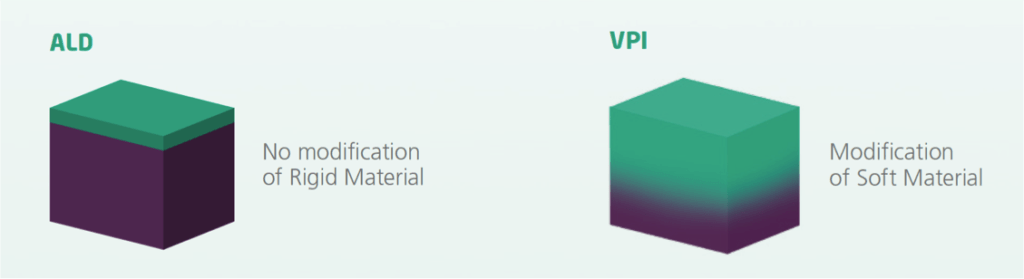

When a dense and solid substrate is exposed to ALD precursors, a thin conformal coating develops at the surface of the material. However, when a soft material is used as substrate, the precursors will diffuse into the sub-surface regions and react with available functional groups.

A schematic describing the difference between conventional ALD resulting in thin-film deposition (left) and the VPI technique resulting on modification of the soft material (right)

Unlike in ALD, the infiltration process does not necessarily have to operate with two distinct precursors. VPI can be conducted by applying single precursor.

ADVANTAGES OF VPI

- Novel way of doping conducting polymers by applying this ALD-derived technique for avoiding the negative influence of the wet chemical doping approaches

- The VPI process not only allows efficient control in the doping level, but also allows solvent-free processing and even top-down doping of already manufactured and shaped conducting polymers

- It can be widely used considering the vast number of conductive polymers known and the equally vast amount of ALD processes that are developed

- Infiltration of transition metals into biopolymers has been shown to unusually change the bulk mechanical properties of those materials

APPLICATIONS

- Fibers (Cellulose, PP, Acrylic…)

- Nanoparticles

- Textiles

- Foams

- Films

- Integrated Circuits

References

- S.M. George. Atomic Layer Deposition: An Overview. Chem. Rev. 2010, 110, 111–131

- R. W. Johnson, A. Hultqvist, S. F. Bent. A brief review of atomic layer deposition: from fundamentals to applications Materials Today 17, 5, 2014

- A. J. M. Mackus, A. A. Bol, W. M. M. Kessels. The use of atomic layer deposition in advanced nanopatterning. Nanoscale, 2014,6, 10941-10960

- S.M. Lee, E. Pippel, U. Gösele, C. Dresbach, Y. Qin, C. V. Chandran, T. Bräuniger, G. Hause, M. Knez. Greatly Increased Toughness of Infiltrated Spider Silk. Science (2009) 324, 5926,488-492.

- J. Hämäläinen, M. Ritala, M. Leskelä. Chem. Mater., 2014, 26 (1), 786–801.

- M. D. McDaniel, T. Q. Ngo, S. Hu, A. Posadas, A. A. Demkov, John G. Ekerdt. Appl. Phys. Rev. 2, 041301 (2015)

- C.W. Kung, J. E. Mondloch, T. C. Wang, W. Bury, W. Hoffeditz, B. M. Klahr, R C. Klet, M. J. Pellin, O. K. Farha, J.

- T. Hupp. ACS Appl. Mater. Interfaces, 2015, 7 (51), pp 28223–28230 ACS Appl. Mater. Interfaces, 2015, 7 (51), 28223–28230